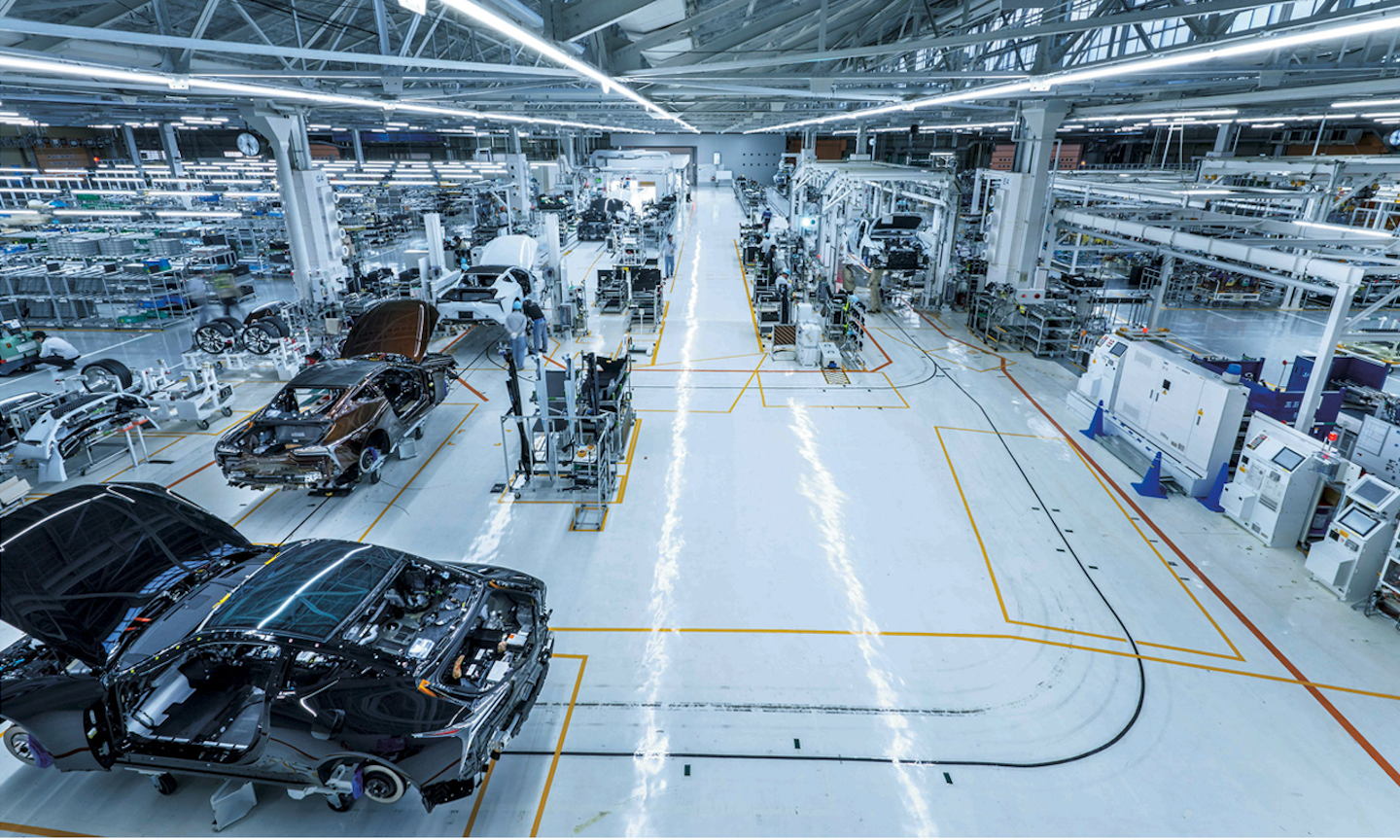

Behind the Scenes: A Look at Lexus Manufacturing

There’s a reason that Lexus automobiles are some of the most luxurious, high-quality vehicles made. Lexus takes special care when it comes to the design, engineering, and manufacturing of its models, utilizing precision practices that have reliably lead to world-class automobiles. Lexus also seeks to revolutionize the way factory work is perceived, going above and beyond to reduce its environmental impact. The automaker is leading the way in manufacturing, ensuring that they stay ahead of the competition.

Manufacturing Reimagined

Lexus may have its roots in Japan, but the automaker produces vehicles all around the world, including right here in the United States. ES models are built in Georgetown, Kentucky. This facility is also home to several Toyota models, and was the first and world’s largest facility for the brand in America. Abroad, Lexus also operates assembly plants in Canada and Japan.

In an effort to create amazing performance vehicles, Lexus has found that it pays to innovate. When creating the Lexus LFA, the automaker needed to revolutionize the way carbon fiber is made, and invented the world’s first 3-dimensional carbon fiber loom. This loom can weave carbon fiber in a circular direction, which results in the superior application of the material. Lexus engineers have since used the same technology for consumer cars, such as the Lexus GS F and RC F.

Lexus has structured its manufacturing process to reflect Japanese culture, with ten Takumi, or master craftsmen, monitoring every aspect of Lexus creation from start to finish. These Takumi train each technician to have a keen eye for detail, deeply scrutinizing each vehicle’s, paint, engine components, and body panels, so Lexus vehicles always meet consumers’ high expectations.

Advanced Testing for Optimal Performance

The last step in the Lexus manufacturing process is a test drive, performed by a skilled performance driver. However, that's not the only test Lexus models are subjected to. Prototype vehicles are exposed to extremely hot and cold temperatures to ensure that the models will be able to withstand the weather, no matter where your Lexus takes you. A wind tunnel is utilized to test vehicles for handling, aerodynamic flow, and wind noise in the cabin. That's why Lexus vehicles are so comfortable in the cabin yet so agile on the road. An innovative virtual crash-testing system allows Lexus to create vehicles that perform well in addition to protecting their occupants.

Protecting Our Environment

In addition to the numerous models with gas-sipping and hybrid powertrains available from Lexus, the brand also focuses on producing those models using sustainable materials and reduced waste. Many of the brand’s facilities are LEED-certified, which is an incredible achievement for assembly plants and a benchmark for environmentally conscious manufacturing. By also using up to 30% renewable plastics and developing a speaker system that uses bamboo-charcoal resin (which they shared with every car manufacturer in the interest of promoting sustainability across the globe), Lexus cements a commitment to a sustainable future in automotive manufacturing.

The team here at Butler Lexus of South Atlanta is just as dedicated to helping you find the luxury model that fits your needs as Lexus design, engineering, and manufacturing teams are to creating some of the highest quality vehicles available. Check out our inventory to see the product of all this hard work and contact us today to learn more.

Image and Video Credit: Lexus